Our Nonstick Coatings Are Made for Gluing Assembly-Joining with Adhesives

Teflon® PFA, Teflon® FEP, Sunoloy® and Wearlon® Coatings are being used for the ease of cleaning of glue pots, adhesive masks, adhesive racks, and thermoforming tooling.

These coatings reduced the cleaning time, thus, saving in labor and down time.

Today, as the need for battery systems continues to grow in the Electric Vehicle (EV) marketplace, using structural adhesives and sealants, our nonstick coatings for tooling fixtures offer proven solutions for the battery pack and module assembly gluing operations.

Ease in cleaning, and reduced maintenance or downtime are just some of the benefits our nonstick coatings bring to battery assembly automation for vehicles and electric drives.

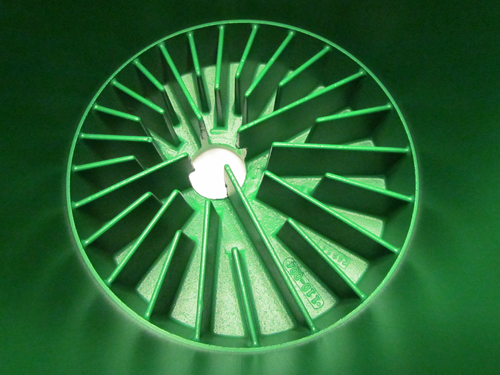

Our nonstick coatings are applied to glue fixtures, assembly assist tooling, masks, buckets, and more for EV battery assembly gluing and adhesives automation.

Let us help you improve your manufacturing environment for cleanliness and productivity, including our nonstick coatings for SMC battery enclosure molds.

Nonstick Coatings Designed to Save You Maintenance and Downtime

As structural adhesives replace fasteners for weight reduction, faster processing, and multi-material joining in the Electric Vehicle (EV) marketplace, Chemours Teflon® and Sunoloy® release (nonstick) coatings offer exceptional performance for battery tooling jigs, fixtures, and pallets, and will help you operate more cleanly and efficiently.

Get the Best Nonstick Coatings for Gluing Assembly

Reach out to us at Sun Coating Company for the latest, most innovative coating solutions available today for nonstick coating for gluing assembly operations and nonstick coatings for SMC battery enclosure molds. Our coatings are proven in the industry.