Sunoloy Coatings

Sunoloy® Coatings are Technologically Advanced and Innovative Coating Solutions.

Sun Coating Company has been providing innovative coating solutions for release (nonstick), wear, and dry lubrication for 60 years. To keep up with the ever-growing demands of the industry―our proprietary, patentable coatings (Sunoloy®) continue to evolve through continuous engineering, trial, and testing with the most advanced materials in the marketplace today―formulated for unrivaled performance, revered by design engineers and manufacturing professionals alike.

Sunoloy® Coatings are used in many diverse industries and market segments including packaging automation, molding, robotic welding, food processing, thermoforming, automotive, adhesives, and so much more. We help make surfaces work better, faster, last longer, and more efficiently with coatings for high release, low friction―coatings tough and durable that resist permeation, flaking, or peeling, that retain their mechanical properties at elevated temperature and protect from abrasion. Many are available in a variety of colors.

These coatings are used around the world, and have the versatility to offer the marketplace an unlimited range of coating possibilities for release, wear, galling, dry lube, corrosion, low coefficient of friction, hardness and many of our coatings meet FDA approval.

Through engineering and testing we have developed the Sunoloy® Coatings to meet specific industry performance requirements. Our Sunoloy® coatings can be found today performing and meeting the demands in the following industries: molding, tooling, paper, plastic and material handling, packaging, food and candy processing, cutting knives, labeling, thermoforming, vacuum forming, welding, rotational molds, glue and adhesives, paint, foam, and maintenance.

What Sunoloy® Coating Technologies Do We Offer?

- EN-Coating Series

- HC-Coating Series

- Anti-Spatter for Robotic Welding

- Non-Stick Coatings for Heat Seal Packaging

- Non-Stick Coatings for Molding

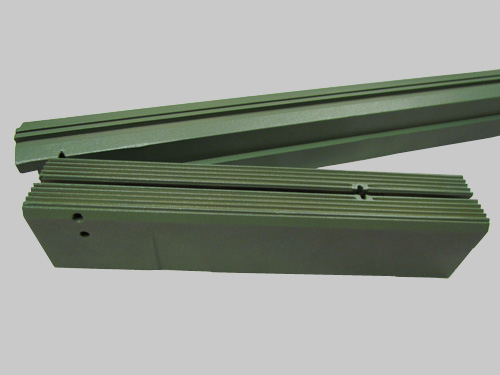

- Non-Stick Coatings for Syntactic Foam Plug Assists

- Non-Stick Coatings for CPET

- Non-Stick Coatings for Polyurethane Foam

- Non-Stick Coatings for Food Processing

What began for us as an original licensed industrial applicator of Teflon® in 1962 remains to this day: our commitment to meeting customer expectations by providing quality coatings and services through teamwork satisfying the requirements of ISO 9001 to continuously improve our Quality Management System. We pride ourselves on providing total customer satisfaction.

We guarantee high-quality polyurethane foam mold coatings and syntactic foam plug assists coatings that extend the life of machinery. Sunoloy coatings are reliable and durable, contact Sun Coating Company to learn more about our non-stick coating company.

Sunoloy® Fluoropolymer Coating Series are unique, proprietary, custom-formulated coatings for remarkable non-stick, low friction, mechanical toughness and protection from abrasion. Resistance to wear and permeation are equally outstanding, which makes Sunoloy® coatings suitable for a wide variety of practical applications.

- PropertiesExcellent Release (Non-Stick) • Low Surface Energy • Non-Wetting • No Peeling • Resist Permeation •Outstanding Protection from Abrasion • Higher Heat Stability • Ultimate Wear • FDA Approved • Multiple Color Choices

- AdvantagesExtend Tool Life • Ease in Cleaning • Improve Quality • Reduce Downtime • Lower Maintenance • Avoid Secondary Operations • And More

- Industries UsedThermoforming • Hot Plate Welding • Heat Sealing • Food Processing • Packaging • Molding • Paint Fixtures • Glues • Pressure Sensitive Adhesives • Anti-Weld Spatter • Medical • Automation • Industrial • And More

Sunoloy® EN-Coating Series are unique, proprietary, interfusions of electroless nickel plating. Combining their conformal coverage with increased hardness, protection from corrosion, high release (nonstick) and low friction, our En-Coating Series creates a “synergistic” effect for a wide variety of practical applications. Surface energies remain the lowest attainable. Bonds are integral with the base material, which means the coatings do not chip, crack, flake, or peel.

- PropertiesTypical Range of Surface Growth Available: 0.0005 to 0.001 inch • Standard Range of Hardness Available: 62-70 (Rockwell C) • Deposition Temperature: 200° F to 750° F • Service Temperature: -250°F to 550°F (Some Sunoloy® EN-Coatings will perform to 1,400°F.) • Release (Non-stick): High Friction (Static/Dynamic): 0.04-0.10* • Friction is a system-dependent parameter, a function of load and mass, distance and rate of travel, hardness, base material, surface finish, counter-surface, temperature, and other factors.

- AdvantagesExtend Tool Life • Ease in Cleaning • Improve Quality • Reduce Downtime • Lower Maintenance • Avoid Secondary Operations • And More

- Industries UsedThermoforming • Hot Plate Welding • Heat Sealing • Food Processing • Packaging • Medical • Automation • Industrial • Plastics • Forming • Guides • Molding • And More

Sunoloy® HC-Coating Series are unique, proprietary interfusions for hardcoat anodizing. Combining a layer of ceramic oxide formed by electro/chemical conversion of the aluminum surface with high release and lubricating materials creates a “synergistic” effect for a wide variety of practical applications. Protection from wear or corrosion is outstanding. Surface energies remain the lowest attainable. Bonds are integral with the base material, which means the coatings do not chip, crack, flake, or peel.

- PropertiesTypical Surface Growth: 0.001 inch ±0.0003 (Total Coating Thickness, including penetration of aluminum, is 0.002 inch ±0.0006)Typical Hardness: 62-65 (Rockwell C)Deposition Temperature: 200°F to 750°FService Temperature:-250°F to 550°F

(Some Sunoloy® HC Coatings will perform to 800°F)Release (Non-Stick): HighFriction (Static/Dynamic): 0.04-0.10*Friction is a system-dependent parameter, a function of load and mass, distance and rate of travel, hardness, base material, surface finish, counter-surface, temperature, and other - AdvantagesExtend Tool Life • Ease in Cleaning • Improve Quality • Reduce Downtime • Lower Maintenance • Avoid Secondary Operations • And More

- Industries UsedPlastics • Forming • Guides • Molding • Thermoforming • Hot Plate Welding • Heat Sealing • Food Processing • Packaging • Medical • Automation • Industrial • And More

Sunoloy® proprietary non-stick coatings are “tough-as-nails” for exceptional protection from abrasion and uniquely-formulated to deliver outstanding release performance. Rugged, impenetrable non-stick surfaces mean savings—reduced downtime and longer intervals between maintenance. Materials comply with FDA and are GRAS (Generally Recognized as Safe). Sunoloy’s proprietary, uniquely-formulated non-stick coatings reflect our commitment to your Ultimate Productivity for optimum food processing.

- Advantages Excellent Non-Stick / Release • Low Surface Energy • Improve Product Flow • Resist Chemical Wash Down • Reduce Product Loss / Waste • Improve Material • Distribution • Resist Permeation • Excellent Adhesion • FDA Approved • No Peeling • Exceptional Protection from Abrasion • Multiple Color Choices

- PropertiesSunoloy® C-Series is a high-temperature coating that extends service life and reduces the replacement cost of nozzle tips. Sunoloy® P-Series offers a unique micro-texture for exceptional spatter release (nonstick) and extended performance life for fixtures and jigs.

Sunoloy® proprietary non-stick coatings are “tough-as-nails” for exceptional protection from abrasion, uniquely-formulated to deliver release unrivaled for both OEM and aftermarket heat seal packaging machinery.

Rugged, impenetrable non-stick surfaces mean savings–reduced downtime and longer intervals between maintenance. Improved mechanical properties at higher temperature assure reliability. Sunoloy’s proprietary, uniquely-formulated non-stick coatings offer one of the largest product lines available today for heat seal packaging-coatings engineered, tailored to your specific needs–a reflection of our commitment to your Ultimate Productivity and perfect heat sealing, every time.

- AdvantagesExcellent Non-Stick / Release • Low Surface Energy • Reduce Changeover • Higher Heat Stability • Exceptional Protection from Abrasion • Maximum Cycle Life • Excellent Adhesion • FDA Approved Versions Available • Increase Product Quality • Hardness to 72 Rc Attainable

Sunoloy® proprietary non-stick coatings are “tough-as-nails” for exceptional protection from abrasion, uniquely-formulated to deliver release and durability unrivaled for both OEM and aftermarket hot plate welding equipment.

Rugged, impenetrable non-stick surfaces mean savings – reduced downtime and longer intervals between maintenance. Improved mechanical properties at higher temperature assure reliability.

Sunoloy’s proprietary, uniquely-formulated non-stick coatings reflect our commitment to your Ultimate Productivity and perfect hot plate welding.

- AdvantagesExcellent Non-Stick/Release • Low Surface Energy • Reduce Changeover • Higher Heat Stability • Exceptional Protection from Abrasion • Maximum Cycle Life • Excellent Adhesion • FDA Approved • Versions Available • Increase Product Quality

Sunoloy® proprietary fluoropolymer and lnterfused Matrix Coatings are custom engineered, “harder-than-steel” low energy surfaces for unrivaled performance. Bonds are integral with the base metal, which means the coatings will not chip, crack, flake or peel.

High release and low friction with protection from abrasion mean savings– reduced downtime and longer intervals between maintenance. Materials comply with FDA and are GRAS (Generally Recognized as Safe).

- AdvantagesExcellent Non-Stick / Release • Low Surface Energy • Improve Product Flow • Reduce Product Loss / Waste • Excellent Adhesion • FDA Compliant • No Peeling • Hardness up to 72 Rockwell C

Sunoloy® proprietary non-stick coatings for syntactic foam plug assists create low stick surfaces for improved product quality and increased tool durability. Impenetrable non-stick surfaces mean savings–reduced downtime and longer intervals between maintenance.

Sunoloy’s proprietary, uniquely-formulated non-stick coatings reflect our commitment to your Ultimate Productivity and Perfect Packaging.

- Advantages Non-Stick / Release • Low Surface Energy • Improve Material Distribution • Use with Transparent Plastic • Allows Deep Draw • Improve Overall Product Quality • Increase Tool Durability • Excellent Adhesion • FDA Approved • No Peeling • Exceptional Protection from Abrasion

Sunoloy® proprietary non-stick coatings offer exceptional protection from abrasion, unlike competitor finishes that wear quickly. Sunoloy® “tough-as-nails” coatings are uniquely formulated to deliver release for years.

Rugged, impenetrable non-stick surfaces mean savings-reduced downtime and longer intervals between maintenance. Our distinct proprietary surface finishes improve heat transfer and wall thickness uniformity. Sunoloy’s proprietary, uniquely-formulated non-stick coatings reflect our commitment to your Ultimate Productivity and perfect packaging.

- AdvantagesExcellent Non-Stick / Release • Low Surface Energy • Improve Material Flow • No Air Entrapment • Better Wall Thickness Tolerance • Improve Material Distribution • Resist Permeation (Plate-Out) • Excellent Adhesion • FDA Approved • No Peeling • Exceptional Protection from Abrasion • Multiple Color Choices for Cavity Identification

Sunoloy® is a high release, demolding coating engineered specifically to prevent polyurethane foam, polyol or isocyanates, from adherence. Its special, non-porous surface morphology enables optimal product quality, eliminates downtime, scrap or defects.

- PropertiesSunoloy® Non-Stick Coatings are revolutionizing the manufacture of urethane foam products - both in the efficiency of process and quality of product, regardless of shape.

For all cast elastomers, rigid and flexible foams, Sunoloy®offers superior demolding and part release, without the expense of release agents. No more pastes, waxes or lubricants or associated cleaning and maintenance. - AdvantagesPerfect Release and Demolding • Optimize Surface Finish Quality • Eliminate Scrap or Defects • Eliminate Cleaning and Maintenance • Compatible with Post-Molding Operations, Such as Painting and Adhesives • Create a Safer, Environmentally Friendly Environment • Improve Surface Quality of Shaped Articles • Bonds to Ferrous and Non-Ferrous Metals

Sunoloy® proprietary non-stick coatings are “tough-as-nails” for exceptional protection from abrasion and uniquely-formulated to deliver outstanding release performance.

Rugged, impenetrable non-stick surfaces mean savings reduced downtime and longer intervals between maintenance. Materials comply with FDA and are GRAS (Generally Recognized as Safe).

Sunoloy’s proprietary, uniquely-formulated non-stick coatings reflect our commitment to your Ultimate Productivity for optimum food processing.

- Advantages• Excellent Non-Stick / Release • Low Surface Energy • Improve Product Flow • Resist Chemical Wash Down • Reduce Product Loss / Waste • Improve Material Distribution • Resist Permeation • Excellent Adhesion • FDA Approved • No Peeling • Exceptional Protection from Abrasion • Multiple Color Choices

Learn More About Sunoloy Coatings Here:

Fluropolymer Series EN Series HC Series Molding (Market) Hot Plate Welding (Market) Heat Seal Packaging (Market) Food Processing (Market) Foam Plug Assist (Market)