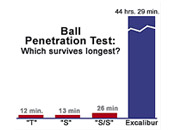

Ball Penetration

The Ball Penetration Test is a widely accepted method of measuring the durability of Fluoropolymer coatings. In this test, a 1/8″ Rockwell stainless-steel ball under a 3,000-gram load is placed on a coated aluminum substrate which is rotated in a perfect circle. The motor driving the substrate is wired to an ammeter to measure the amount of current required to turn the motor. The output is fed to a strip chart, recording the current.

The Ball Penetration Test is a widely accepted method of measuring the durability of Fluoropolymer coatings. In this test, a 1/8″ Rockwell stainless-steel ball under a 3,000-gram load is placed on a coated aluminum substrate which is rotated in a perfect circle. The motor driving the substrate is wired to an ammeter to measure the amount of current required to turn the motor. The output is fed to a strip chart, recording the current.

When the ball penetrates the Fluoropolymer surface and touches the metal substrate, it drags, drawing more current and causing the strip chart to record a radical change. The time to failure is then noted.

In this series of tests, under precisely the same conditions, coating “T” lasted 12 minutes, coating “S” lasted 13 minutes, coating “S/S” lasted 26 minutes. Yet Excalibur lasted 44 hours and 29 minutes, more than 100 times longer than all three coatings.

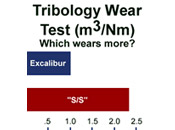

Tribology Wear Test

In tests conducted by an independent testing laboratory in the United Kingdom, coated steel panels were fixed to a base plate which was moved back and forth with a fixed stroke length.

In tests conducted by an independent testing laboratory in the United Kingdom, coated steel panels were fixed to a base plate which was moved back and forth with a fixed stroke length.

A steel pin with a polished, spherical end was held stationary against the moving coated panel under a load of 10 N. After approximately one hour, the wear volume was measured by laser profilometry. Under identical test conditions, “S/S”, the leading high-priced competitive coating, suffered 130 percent more wear than Excalibur.

Learn More About Excalibur® Fluoropolymer Coatings Here:

Excalibur Fluoropolymer Coatings Why Excalibur Fluoropolymer Coatings? The Excalibur Process Excalibur Test Results When to Use Excalibur