Heat Seal Packaging Coatings

Sun Coating Company provides one of the largest lines of coatings available for the packaging industry.

Sun Coating Company provides one of the largest lines of coatings available for the packaging industry.

Our Sunoloy® coatings is a Proprietary Coating that offers process improvements, enhanced performance, and longer wear compared to other coating solutions. Sunoloy® Coating Solutions will exceed original equipment manufacturers coatings. In most cases, we are already working with your OEM to improve their equipment.

We currently coat heat sealing blades, heat sealing jaws, heat sealing plates, heat sealing heads, heat sealing blister pack packaging, fill tubes, shrink wrap machines, bagging machine, plastic forming equipment, thermoforming tooling, and hot plate welding.

We offer an extensive line of coatings for the packaging industry, including Chemours Teflon®, Whitford Xylan®, the Sunoloy® formulations, and more. These tough, durable, release coatings are used on Vertical Form Fill and Seal (VFFS), Horizontal Flow Wrappers, Air Pillows, Blister, Baggers, Printing, Labeling, including FDA-compliant versions for direct food contact, beverage, pharma, and the life sciences.

Sunoloy® our Proprietary Coating Solutions

Hardcoat/Teflon® Interfusion

EN/Teflon® Interfusion

Improve Your Automation Output

Whether your adherents are plastic, flexible, corrugated, solid-fiber, paper, foil, or biodegradable, we have a nonstick coating solution for all your high-speed packaging needs. Special proprietary reinforcements are available to enhance protection from abrasion. Ceramics can also be incorporated for coating for packaging, creating uniformity in heat transfer superior to virgin aluminum.

- What Do We Coat Currently?Chemours Teflon®, Whitford Xylan®, and Sunoloy® formulations― through our coating services―will ensure optimum performance every time without sacrificing appearance. For heat seal packaging, heat sealing blades, heat seal jaws, heat seal plates, blister pack packaging, shrink wrap machines, baggers, forming equipment, thermoform tooling, and hot plate welding―we have nonstick coating solutions proven in the industry.

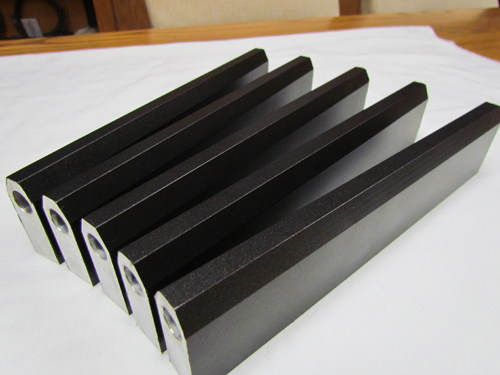

- Heat Sealing Blades For high heat and resistance to abrasion, we offer myriad nonstick coating solutions for long-lasting, high-temperature release, outstanding performance life. Coating thickness is comparatively thin to ensure heat transfer while protecting from wear and rust or corrosion.

- Heat Seal JawsGet the most from your heat seal jaw. Through an array of high-performance nonstick coatings available today, you can improve your design and operating conditions, elevate performance with any packaging material, speed, or sealing requirement. The coatings are resistant to high heat, flaking, chipping, or peeling.

- Heat Seal PlatesFor the manufacture of cups, labels, lidding, or plastic films―your most sensitive materials joining―let us help you prevent sticking and build-up between cycles that would negatively affect the quality and appearance of subsequent welds. We have the best coating solutions for heat sealing plates, designed specifically for maximum efficiency and minimal equipment downtime.

- Heat Seal HeadsChemours Teflon®, Whitford Xylan®, and Sunoloy® formulations ensure an improved quality seal when it comes to coating for packaging. Coating thickness is relatively thin so as not to affect heat transfer of the heat seal heads yet tough and durable.

- Heat Sealing Blister Pack Packaging Blister pack packaging is one of the more economical methods for heat seal packaging manufactures. Reduce waste or downtime with our coating solutions proven in the industry, standing the test of time.

- Shrink Wrap MachinesWhether vertical, horizontal, orbital, we offer myriad choices in nonstick coatings to help maintain continuous motion or speed, achieve a quality wrap, more reliable sealing, and reduce waste―without sacrificing appearance or performance. FDA-compliant coatings for packaging are also available.

- Bagging MachinesOur nonstick coating solutions are proven with high-speed bagging machines, forming, filling, and sealing. Hardness is attainable to 70 (Rockwell C).

- Plastic Forming Equipment and Thermoform ToolingFor plastic forming equipment (vacuum forming, thermoforming) our nonstick coatings are proven in the industry to be long-wear, with high-temperature stability. They do not migrate, transfer, or peel. Special formulations resist permeation, allow ease in product stacking without vacuum lock, and are available in a variety of colors.

- Hot Plate WeldingFor hot plate welding requiring a heat-resistant nonstick coating, we have your answer. Impenetrable nonstick coating heat seal packaging surfaces mean savings, reduced downtime, and longer intervals between maintenance.

Coating for Packaging & More

Whether equipment needs coating for packing or heat seal packaging, Sun Coating Co. offers high-quality coating services for longer-lasting equipment and parts. For more information on coating for packaging services and heat seal packaging coatings, contact us today.